Compare Light Diesel Oil (LDO) and High-Speed Diesel (HSD) in this detailed guide. Understand their differences in composition, applications, and cost advantages to make an informed choice. Fuel choice significantly impacts operational efficiency and cost management in various industries. Light Diesel Oil (LDO) and High-Speed Diesel (HSD) each serve unique applications and requirements. This guide provides a detailed look into LDO vs. HSD, explaining key distinctions in composition, applications, and performance.

1. Understanding Light Diesel Oil (LDO)

Composition and Key Characteristics

Light Diesel Oil, or LDO, is a blend that includes residual oil, offering an economical fuel solution for non-automotive applications. Key features of LDO include:

– Moderate Heating Capacity: Ideal for lower energy needs.

– No Preheating Requirement: LDO is simple to handle in industrial settings.

– Affordable Option: Preferred by industries requiring economical fuel for heating and moderate engines.

Common Applications of LDO

LDO is widely used for:

– Industrial heating applications, including furnaces and boilers

– Low- to medium-speed machinery

– Agricultural equipment where high-speed fuel isn’t essential

Its cost-effectiveness and ease of storage make it highly appealing for industries focused on operational budgets.

2. Overview of High-Speed Diesel (HSD)

Composition and Benefits of HSD

High-Speed Diesel (HSD) is a refined fuel specifically designed for high-speed, high-performance engines. Known for its efficient combustion properties, HSD powers:

– Automotive Engines: Trucks, buses, and cars

– Heavy-Duty Machinery: Mining and construction equipment

– Power Generators: Essential for industries needing stable, reliable energy

High-Speed Diesel Characteristics

HSD’s advantages include:

– Clean Combustion: Especially with ultra-low sulfur variants.

– High Energy Density: Suitable for engines with high operational demands.

– Environmental Compliance: Designed to meet emissions standards, making it preferred in regulated industries.

3. Comparing LDO and HSD: Key Differences

| Feature | Light Diesel Oil (LDO) | High-Speed Diesel (HSD) |

|---|---|---|

| Refinement and Composition | Lower refinement; more economical | High refinement; cleaner combustion, high energy |

| Emissions and Environmental Impact | Higher sulfur content; larger environmental impact | Lower sulfur variants; meets emissions standards |

| Application Suitability | Moderate-speed, cost-sensitive applications (e.g., heating) | High-performance engines, power-demanding machinery |

| Cost Implications | Lower cost; ideal for heating and low-speed machinery | Higher cost; optimal for high-performance tasks |

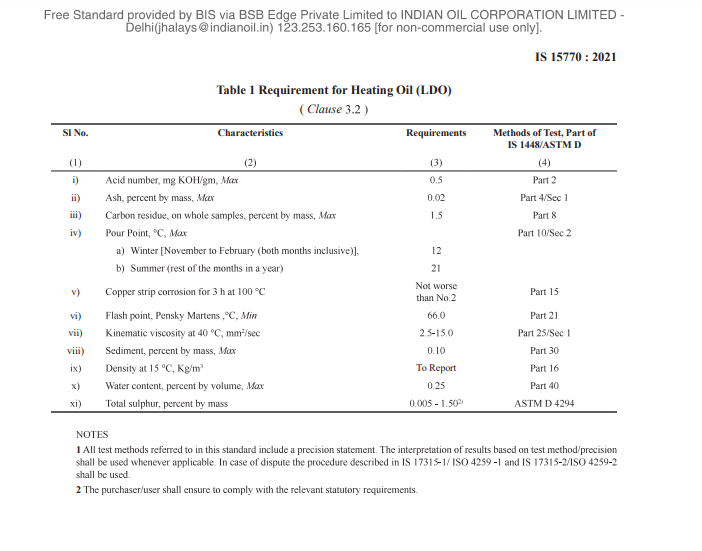

Here’s the table format for the provided data on the characteristics of High-Speed Diesel (HSD) and Light Diesel Oil (LDO):

| Sl No. | Characteristics | HSD | LDO | Method of Test (Ref to IS 1448) |

|---|---|---|---|---|

| i) | Acidity, inorganic | P : 2 | ||

| ii) | Acidity, total mg of KOH/G, Max | 0.30 | P : 2 | |

| iii) | Ash, percent by mass, Max | 0.01 | 0.02 | P : 4 |

| iv) | Carbon residue (Ramsbottom) on 10% residue, percent by mass, Max | 0.35 | 1.5 (on whole sample) | P : 8 |

| v) | Cetane number, Min | 45 | P : 9 | |

| vi) | Pour point, Max | 6°C (winter), 18°C (summer) | 12°C (winter), 21°C (summer) | P : 10 |

| vii) | Copper strip corrosion for 3 h at 100°C | Not worse than No. 1 | Not worse than No. 2 | P : 15 |

| viii) | Distillation 90% volume recovery at °C, Max | 366 | P : 18 | |

| ix) | Flash point (Abel, °C, Min) | 32 | P : 20 | |

| Flash point (Pensky-Martens, °C, Min) | 66 | P : 21 | ||

| x) | Kinematic viscosity, cSt, at 40°C | 1.8 to 5.0 | 2.0 to 15.0 | P : 25 |

| xi) | Sediments, percent by mass, Max | 0.05 | 0.10 | P : 30 |

| xii) | Density at 15°C, kg/m³ | 810 – 845 | To be reported | P : 32 |

| xiii) | Total sulphur, percent by mass, Max | 1.0 | 1.8 | P : 33 |

| xiv) | Water content, percent by volume, Max | 0.05 | 0.25 | P : 40 |

| xv) | Cold Filter Plugging Point (CFPP), Max | 9°C (winter), 21°C (summer) | P : 110 | |

| xvi) | Total sediments, mg per 100 ml, Max | 1.6 | A |

This table summarizes the key parameters and testing references for HSD and LDO as per IS 1448.

4. Selecting the Right Fuel: LDO vs. HSD

Factors to Consider

1. Operational Needs: If your business relies on high-speed engines, HSD offers the best performance, whereas LDO suits lower-speed, cost-sensitive equipment.

2. Environmental Regulations: HSD aligns with modern emissions standards; LDO may require emissions control mechanisms in certain locations.

3. Budget Considerations: LDO is the economical choice for heating, while HSD’s benefits justify its cost for high-power engines.

Choosing between LDO and HSD depends on evaluating these factors to align fuel selection with business needs effectively.

Conclusion

In summary, Light Diesel Oil (LDO) and High-Speed Diesel (HSD) fulfill distinct roles in industrial and automotive sectors. LDO is a practical, cost-effective solution for heating and moderate-speed machinery, while HSD is essential for high-speed engines and clean, efficient combustion. Proper fuel selection maximizes efficiency, complies with regulatory standards, and enhances long-term operational performance.